I’ve been working with manufacturers since I launched my first Airsoft business in 2009. And I always have people email me and ask me about manufacturers.

There seems to be confusion when shopping on Alibaba, AliExpress or looking for domestic products if you’re talking to a manufacturer or a trading company.

In this article I hope to clear up the confusion and guide you in growing your business abroad.

A manufacturer is a company that makes finished products from raw materials and sells them to a business at a profit. The business then sells them to the end customer for a profit.

Generally a manufacturer wouldn’t sell products directly to the end customer but it doesn’t mean they don’t try sometimes.

Manufacturers sell their products to either retailers or wholesalers. A retailer can sell their products either in a physical “brick and mortar” store or on an online eCommerce selling platform.

During the manufacturing process they typically only make large orders for established businesses. However, every manufacturer has a different minimum order they are willing to create in their factories.

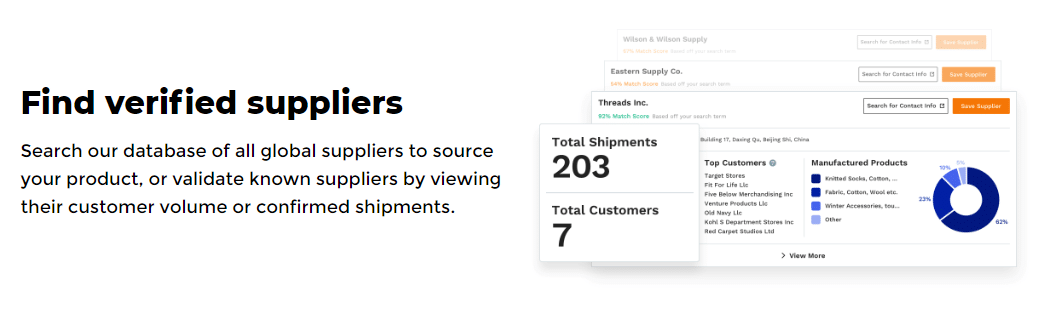

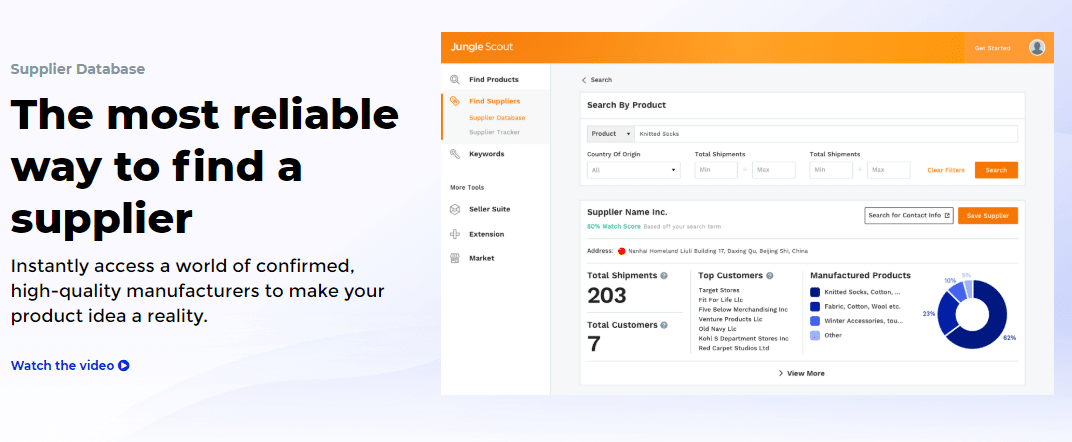

Check Out The Supplier Database

Some factories are able to make small quantities and still make a profit but other factories because of the cost to operate their machines need to produce high minimum order quantities (MOQ) to make a profit. If you’re looking for reliable injection molding services for prototypes and production parts, it’s important to find a manufacturer that can accommodate your specific production needs.

A reputable manufacturer will be certified with the international manufacturing standards: ANSI/ASQ Z1.4, ISO2859 Special Inspection Level S-3.

Every manufacturer knows these international standards and has the ability to meet them if they agree to a yearly inspection of their facility.

Differences Between Manufacturers, Distributors, Wholesalers and Retailers

It can sound overwhelming to hear all of these terms when you’re just starting out but they’re simple to explain.

This is the complete private label supply chain and for the most part every link in the chain is necessary. Each one depends on the other to make a profit and get the product to the end customer at the most affordable cost possible.

I’ll explain with an example:

The manufacturer create 1,000 units of a product. They have 2 options, sell directly to a wholesaler that can buy 1,000 pieces or work with a distributor that knows multiple wholesalers that can buy the 1,000 units.

Wholesalers can buy 400 units from one distributor and 400 units from another distributor and 200 units from a 3rd to complete a retailers entire order. If you’re a small business with only a few products then you can work directly with multiple manufacturers.

But let’s say you have 100’s of products…

As a retail store you can’t manage all of that by yourself but you can work with 2 to 3 wholesalers that work with multiple distributors to get you all of your products. So the larger you are the more it makes sense.

Wholesalers have the flexibility to buy multiple products in bulk from either distributors or manufacturers and pass those savings to retailers. Retailers generally wouldn’t be able to afford the high minimums charged by factories.

Overseas Manufacturing

It’s common in the United States to sell a product not made in the US. Typically the product is made in China or Southeast Asia. Overseas manufacturing is when the process of raw materials to finished goods is made in a different country than where it’s sold.

A retailer can “offshore” their manufacturing process because labor and raw material costs are lower in other countries. A company that is famous for overseas manufacturing is Apple.

They source their products from factories all over the world and send all the pieces to Taiwan to a company called Foxconn. There, engineers and factory workers put all the pieces together to create the final product.

Then Apple turns around and sells the phone in the United States.

Now let’s look at the different types of manufacturing…

Finding Safe Manufacturers

We partnered with JungleScout to put together a supplier/manufacturer database to help you find the right factory for your products. If you want to check it out, it’s right here.

Check Out The Supplier Database

3 Different Types of Manufacturing Production

Generally manufacturing is straight forward. They purchase raw material or part components to finish a product to meet customer demands. They sell the product at a high enough price to cover costs to manufacture with a small profit. A factory can operate one of three different types of production processes.

- Make-to-Stock (MTS)

- Make-to-Assemble (MTA)

- Make-to-Order (MTA)

Let’s quickly go over each one individually…

Make-to-Stock (MTS)

This is a production method that anticipates customer demand. It can either be seasonal demand or typical demand given a products history to sell. The retailer will forecast demand based on historical numbers and the factory makes it.

It’s possible that there might be a slight over-production and the excess products are liquidated at a loss. Or there’s a shortage and the product sells out. There’s usually enough of a margin in the products to sustain an over production and still do well. It’s preferable to overestimate and cover the loss with the margin than sell out and not recoup costs.

MTS helps protect against high production costs because you only make what you need based on historical demand. The differences are usually minimal. Factories are able to have a consistent stream of work and plan their production better.

Make-to-Order (MTO)

In this process the manufacturer waits for the order to come in. This allows the retailer to control their inventory and know exactly how many units they need to sell. MTO allows lead time for the customer to make modifications to the product. The retailer is able to easily prevent over production because they’re only looking at a few months ahead.

This isn’t a favorable manufacturing operation for the factory even though it’s the most common because the factory is doing nothing if orders don’t come in.

Make-to-Assemble (MTA)

In this manufacturing process a factory will make the components of a product in anticipation that an order will come in and then they assemble the part. The problem here is that if the order doesn’t come in then the factory has a large number of useless components. However, with reliable forecasting both the factory and the retailer will get products produced quickly and at an affordable price.

Avoiding Risks is Important

Regardless of which manufacturing method you choose, all three types come with risks you need to look out for. If you order too many products then you can have an overstock and flood the market and drop prices. But if you don’t meet demand your customers will go somewhere else.

If you’re selling on a marketplace like Amazon, then running out of stock will drop your ranking. It’s the manufacturer’s responsibility to make sure they’re making a great product. But as a fail safe it’s the customers responsibility to hold the factory accountable and test products constantly. Placing small test orders become more important the bigger your business gets and you need to put the customer first.

The goal is to keep production costs low and keeping a high quality standard as the orders become larger. There are companies that are willing to visit factories and perform quality checks on behalf of retailers.

Wrapping this up…

Something important to remember as an online seller is to create, nurture and maintain a relationship with the factory you buy products from. A good relationship is important to prevent quality disasters and missed deadlines.

If the factory knows you always place orders with a reasonable timeline and treat them with respect then they are more willing to work with to lower costs. Manufacturing in general is a simple process and the only way to learn more about it is to actually place orders and work with different factories.

Starting is always the most difficult part but if you need help finding suppliers and factories to create your products at a reasonable price we can help. We have connections with companies that help small retailers get products made cost effectively.

Reminder: We partnered with JungleScout to put together a supplier/manufacturer database to help you find the right factory for your products. If you want to check it out, it’s right here.

Check Out The Supplier Database

Additional Resources You Might Be Interested In: