What if you could take a napkin sketch of an invention idea and have a finished product in less than 6 months?

Because you don’t need to be a huge company or have traditional investors to create a product and start a business around it.

All you need is a blueprint to get your ideas out into the world.

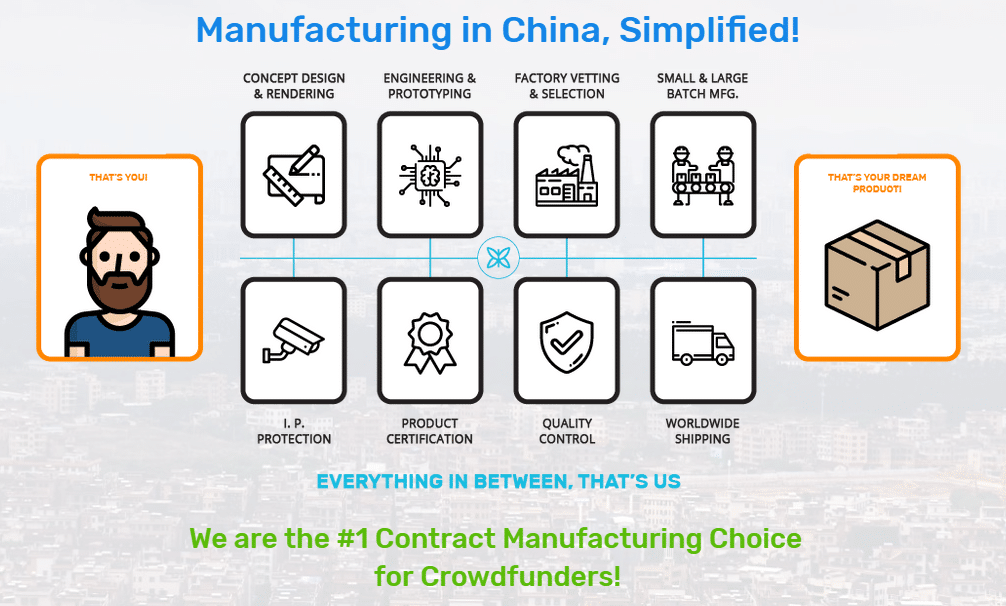

We brought in Josh Fairbairn from Morpho Manufacturing to help us out. Josh moved to China just a few years ago because he saw the rise in Kickstarter projects and knew that manufacturing in China was going to blow up.

His company, Morpho Manufacturing is a recommended manufacturer on both Kickstarter and Indiegogo. These Kickstarter businesses are going to Josh saying: “Hey, we got a product but we don’t know how to make 10,000 pieces in the next three months to satisfy all the backers.”

They’ve mastered the process of taking new product ideas through initial prototyping, sample production runs and into mass manufacturing affordably at ultra-high quality. And he’s doing that all in four to six months per product.

Table of Contents

Let’s start:

Investors and Developing a New Product

No, you don’t need traditional bank investors or business plans to develop a new product. You need a platform like Kickstarter or Indiegogo to find people that want to invest in your idea. That’s how you can save money on validating your product idea before launching a complete production.

10 or 20 years ago if you wanted to create a new product you needed to be a national corporation like Walmart. Or you needed to have the resources to have an entire supply chain set up. You were looking at possibly tens of thousands of dollars to invest and a few years to get to market. But with the growth of crowdfunding and Chinese manufacturing the timeline can now be four to six months.

Crowdfunding a New Invention

It’s the most cost effective way to validate a business idea. The lean startup method describes that you want the minimum viable product (MVP). Crowdfunding allows you to figure out if your idea is worth pursuing before investing too much money . It a great tool for MVP validation of a new product or invention. And it’s a valuable framework to use at least while starting out with limited funds.

That’s what lead to the initiative we started called First to Market (FTM). It means that we can take a napkin sketch all the way to a crowdfund ready product in four to six months. That way when you raise the money you need, everything is ready to go after the campaign.

FTM is a four-step process.

We work with people that come to the table with a napkin sketch. They only have an idea about what they want to do, but they have no idea how to do it.

The First to Market Manufacturing Process (FTM)

Let’s go over the whole process needed to develop a product…(with an example)

1. 2D conceptualization (Napkin Sketch)

2. 3D engineering (Bill of Materials)

3. 3D rendering (Solidworks, AutoCAD, Autodesk Inventor)

4. CNC prototype (Local or Overseas Manufacturers)

The goal is to create a functional prototype with the science to back it up.

The science behind the product needs to be sound because you get a lot of trolls either on Reddit or in the comment sections below the campaign. They’ll claim there is no way your product works and can derail your entire campaign. But if you go through the 4 step process and have a prototype that works and make a video then both Kickstarter and Indiegogo won’t have anything to say.

FTM Product Example: CubCoats

One of my favorite examples is a company called Cub Coats. They were already making a buzz in the valley before coming to us. It’s a zipper hood sweater that folds into itself and becomes a stuffed animal.

The founder of this company is Zach Perch and he came to me one day and said:

“I have this crazy idea and I think it’s just going to kill it.”

And we started with what he was working on with different manufacturers. Generally if people have been working with other manufacturers, they understand the pain of developing a product.

Since they want to avoid that pain as much as possible, our pitch was simple – get the product done quickly for a fair price without headaches. The prototypes they had at the time were hideous. It didn’t function properly or looked cool. There was a bulk in the hood that was just ridiculous.

It’s important to quickly create new versions as often as you can. And we did that by working directly with our engineers at the factory. We were able to get this product to a good point in six months.

Normally textile development can be as little as a month but to become a $50 million dollar company you need to have the product perfect. They tried with so many different factories but it wasn’t turning out the way they needed it to. We created a team of about 10 people to work on this product basically until it was ready.

We took the product through 3 phases…

Phase 1: Scoping Phase 10-14 Days

The first part of what we do is understanding your entire product and what’s going to need to be involved. The scoping phase as we call it would take between 10 to 14 days. And in that time we’ll work with our customers to build a “QCSD” a quality control standard document.

Then we go through every single eighth of an inch of the product. And we’ll try to understand exactly what it is that you’re trying to build. Most factories will do that scoping phase overnight and I think that’s the wrong way to do it.

We need complete objectivity when it comes to product development because if you do most of the heavy lifting in the beginning then there’s less of a chance to have quality control issues. You have to get everything objective on paper and defined by the client. Since most of our clients are startups and the room for error is small.

Phase 2: Initial Prototype Phase 14-60 Days

After phase one is done we moved into an initial prototype. And that’s dependent on the product. Textiles will usually be quicker but if it’s something like electronics and development is needed the timeline is longer. But the range of 14 to 60 days standard for development and prototyping.

Sometimes with the development of a circuit board where engineers are very involved then the timeline is longer. In this phase,we send our prototype to our customers with the quality standard document. They normally like to look over both of those things together. The first prototypes are not going to be perfect. So the customer will go over that with a fine-toothed comb and then come back with revisions.

Phase 3: Create a Mass Production Sample 14- 21 Days

Once the customer has made all the changes to the prototype we move on to a mass production sample. With a production sample there’s little development so the turnaround time is quick. It just deals with final small changes.

But the timeline is also dependent on the complexity of the product. There’s such a wide variety of products, it’s better to be safe and plan on longer timelines. More complex detailed type product it could be 12 months. In general we’re trying to cut it down to four to six months on almost anything.

After the product is created most people want to know about certifications to prove to the customer that the product is safe.

New Invention Product Certifications

We’re not attorneys but we’re basing our answers on personal experience. There are thousands of different certifications. Again, I’m a big believer in the (Minimum Viable Product) MVP. So if you’re at a point where you’re selling a lot of products, then not having certifications can quickly become a liability. But if you’re not selling anything yet, then I would focus on first being able to sell your product.

I believe it’s more of a marketing question because there’s just so many different types of certifications and most of them have big price tags. If you’re scaling up, it’s definitely a good idea to get those things so you don’t have liabilities for your product.

It’s one thing to read about the steps used to create Cub Coats but most people don’t understand what steps are necessary to create functioning prototypes. Without being overly complicated your product most likely will only have metal(aluminum) and plastic. It’s helpful to understand the manufacturing techniques you’ll possibly need on your products to see what’s possible.

With that being said…

What Prototyping Techniques Exist?

CNC Milling

Milling is a process used to rapidly cut solid plastic and metal blocks into final parts. You can make CNC prototypes that are going to look like the finished product when it’s mass manufactured. Even if you’re doing a purely plastic product that’s going to be injection molded in the future you can make a CNC prototype before spending money on a die.

The reason people don’t go right to injection molding is because it’s expensive. Every mold could be in a range between $5,000 and $20,000 dollars. When you need a prototype to do a Kickstarter we recommend having a CNC prototype made. You can do your promotional video and then if you do raise the money you can go ahead and pay for the tooling.

Rapid Prototyping/3D Printing

I wrote a bit about 3D printing in a quora post not giving it much praise back in 2017. But in just about 2 years the technology has improved to create great prototypes.

3D printing is an effective way to quickly see iterations of your design. As a manufacturing method 3D printing is not at the place to produce mass consumer goods. But it can help you save money and time on design.

A CAD services company can help refine your designs before 3D printing, ensuring they are optimized for functionality and manufacturability.

The best use for 3D printing is rapid prototyping. You’re able to see how all your pieces fit together and if your design actually works the way it’s intended to.

This is preferable to dropping thousands of dollars to get a traditional prototype. You’re able to see if you want to spend the money for tooling. People have become our customers in the past and told us they’ve spent $30,000 on tooling just to have poor product dimensions.

3D printing closes the gap of opportunity for those types of mistakes and it’s definitely something that we play with in the early stages of product development.

Textile Manufacturing

So what do you do if your product is a wallet or a pair of leather work gloves?

Well… those types of things aren’t as expensive to prototype.

We actually did a leather product for a now defunct company called Kendall and Hide.

They raised about 3 million on multiple Kickstarter projects.

When you’re doing a leather/textile type product the prototyping cost doesn’t require tooling. It’s just cutting fabric and sewing it together. So when you do products with textiles, you’re hoping that you’re able to do it by hand.

Okay, but what about patents?

Because plenty of first time entrepreneurs fear going public with their ideas before the prototyping phase.

Let’s see:

Patents and Crowdfunding Campaigns

Again, I’m not an attorney and nothing I say here is giving legal advice. But I’m basing my answers on life experience.

And I have a strong opinion that as an entrepreneur in 2019 execution is the new patent. The reverse engineering world is just insane and if you’re the first to market then you’ll be the name people remember.

The truth is that American patents and Intellectual Property protections don’t matter in China. You would need to pay for IP protection in China which is expensive and doesn’t guarantee anything.

Here’s a quick story:

When I came to China Beats by Dre, we’re getting big and I was designing my own headphones. I wanted to make a pair of expensive headphones and my sourcing agent brought me to the factory where they were making beats.

I couldn’t believe it, they’re a company that is now sold to Apple. It was unbelievable that I could just stroll into this factory like it was nothing.

So I looked around and the one brand that you never see good copies of is Apple. That discovery became the foundation I built my company on. And so I went to work on understanding what they did and how they did it.

This is a whole post on it’s own: (How Everyone Should Protect Their Intellectual Property Like Apple)

TL;DR: Apple uses a company called Foxconn. They’re the ones in charge of manufacturing iPhone’s. They’re getting all of the glass sent to their facility along with the circuit boards, aluminum milled casings, and the rest of the iPhone components all from completely independent Chinese factories and put it all together at their facility. No single factory knows what they’re making. Afterwards, Foxconn does the quality control and then the iPhone is shipped out from there.

So what does this mean for your invention?

A New Way to Protect Intellectual Property

We have an assembly plant where we pay the costs of the employees and all the overhead is ours. We contract out all the different pieces of your product to our trusted supply chain. Essentially you’re going to outsource the entire supply side of your business and sign a non disclosure with us.

Why Speed is More Important in Product Development

The truth is that patents are expensive, so what are you supposed to do if you can’t shell money out for a patent?

Here’s another story:

I’m sure everyone reading this is familiar with fidget Cube. I actually wrote a medium blog post last year “how a six point five million dollar Kickstarter campaign f** up.”

TL;DR: They raised over $6 Million on Kickstarter and contracted a single factory listed on Alibaba to source and manufacture the entire product. After the funding round they went over to China and the factory made a mistake on the mass production order for the fidget cubes. So while they fixed the problem, the factory saw the high demand for the product and loaded the rejects out the back of their factory onto trucks. Then distributed them internationally before Fidget Cube was available from Antsy Labs.

If these guys had done things the right way then it would be the beginning of their story. Instead, because of scammers there were hundreds and hundreds of people making fidget cubes and similar products within three or four months. Not only is speed important but preparing yourself and protecting your product will help reduce risks.

Understanding Local Laws

That’s why it’s important to understand the local laws of where you are manufacturing. In China, there is a document known as a NNN Agreement (Non-Disclose, Non-Use, and Non-Compete) that is enforceable by local law to avoid any intellectual property issues. As well as a protection against the supplier competing with your product or using your designs and manufacturing implements.

Remember, an American NDA is NOT enforceable in most other countries, and so an understanding of local law is imperative to protect your IP.

Wrapping this up…

Don’t go at this alone and be stuck on the idea phase forever. Get your idea off the ground.

Most people are afraid that someone is going to steal their ideas if they talk about it to the wrong person. That’s where we come in…

In the beginning you don’t have sales, money to pay for lawyers or patents but you have the ability to move quickly. Launch the best product on the market before anyone else and pay for attorneys once you’re making sales.

Kickstarter is the perfect way to validate your product idea to the masses and turn your ideas into a business.

You need to work with trustworthy factories and develop a relationship with them.

We can sit down with you and help you create functioning prototypes while protecting your intellectual property.

Our entire network can help you launch your new product and make sure that no factory knows your final product. That way you can start your entrepreneurial journey on the right foot.

If you have any questions or want to know more about Morpho Manufacturing please comment below! Using the Startupbros link to start developing a new product with us will give you some special bonuses too!

Special Offer…

We have a completely updated and brand new Amazon business course that teaches first time entrepreneurs how to launch their very own physical product Amazon business. Our clients have access to exclusive members only discounts to resources that can help you launch quickly. If you want to check that out and see if it’s right for you click here…