Amazon inventory management is not a “sexy” subject.But the truth is, even a lot of top sellers are missing out on decent amounts of profit. Due to their inventory management not being as effective as it could be.

So, while those marketing strategies are awesome (and necessary), don’t neglect the role of Amazon inventory management for shoring up your bottom line and helping you to grow your FBA business.

In fact, I’d go as far as to say that managing inventory poorly is one of the biggest reasons sellers are not achieving the results that they could be.Let’s take a closer look:

Here’s What We’re Covering:

- Why Inventory Management Is Important

- Why Do Stockouts Happen?

- Better Inventory Management

- Lead Time

- Ordering New Products

- Wrapping This Up…

Why Inventory Management Is Important

The fundamental premise of Amazon inventory management is that sellers should have the right amount of stock in place at the FBA warehouse at all times. Running out of inventory before you get new stock prevents you from making sales. Too much inventory on the shelves keeps your money tied up.

The most experienced sellers focus on marketing strategy or optimizing listings for Best Seller Rank they leave inventory management somewhere near the bottom of the list. Take a look at these next important inventory management factors and you’ll see why this is a mistake:

Stockouts

Running out of stock may not sound like a big deal, you just order more and get on with it, right?

Not so:

It’s not just missing out on revenue from sales that you have to worry about. If you run out of stock, it’s the impact that it has on your overall performance on Amazon.

What happens when you run out of stock? Amazon takes your product out of search results if you’re the only seller for that particular page and a visit to your page will show the stock as unavailable. Instead, customers will buy from competitors who have stock available.

This matters because the second impact of a stockout is on your Best Seller Ranking. You work hard optimizing your listings, but part of the Best Seller calculation uses sales velocity. Being out of stock means you have no sales velocity.

In the meantime, your competitors are improving their Best Seller Rank because the sales you may have landed are now going to them.

Let’s say:

Your products are out of stock for two weeks and you start with a Best Seller Rank of somewhere around 15,000.

Within that time period, your ranking could easily drop to 25,000 or 30,000, then once you are back in stock, it takes a while to recover to where you were before. This impacts your sales velocity if you push further down the search results.

Excess Inventory

When your inventory is not turning over fast enough, it is figuratively like leaving cash on the shelf. While product languishes at the warehouse, if your operations are tight, you may find that you just don’t have the capital for investment in new inventory.

If you’re wondering how to finance a new product, the first place I would look is within your existing inventory. We often find that, especially once a seller has a number of different products, they can overlook the fact that something isn’t performing as it should.

You might be wondering

Why Do Stockouts Happen?

A lot of people say “I didn’t order enough units”.

Often the reason is more the fact that you didn’t reorder fast enough.

Think about when to reorder so that you can get the right balance between not running out of stock and not having too much in inventory.

I sat down with Greg Mercer of Jungle Scout a while back and looked at some of his product data. (he uses Forecastly, our Amazon inventory management tool)

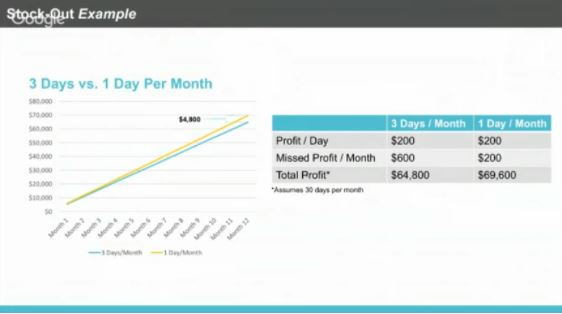

Stock outs alone across a period of 90 days, he had missed out on close to $3000 on profit. This he largely attributed to not reordering on time. It’s an easy mistake to make, especially when you’re busy with other parts of your business – I do the same in my own businesses.

You might think a few days of stock being out here and there won’t really matter, but it can soon add up, especially if you look at it as a whole across the year. Even your lower-performing products can make a significant difference.

Look:

In the graph below, the difference in profit should pay for marketing, or an order of new product.

Better Inventory Management

The answer to avoiding stock outs and managing inventory better as a whole is to get better at:

a) Monitoring your inventory.

b) Forecasting your needs accurately.

This involves the management of a few important numbers, which is why sellers often procrastinate over it and would prefer to focus on marketing strategy. It might seem complicated at first, but once you familiarize yourself with a few important terms that you need to manage, it’s really not too difficult.

I created a tool in Excel which you can access for free here, but check out a few of the terms explained below as well:

Lead Time

This is one of the key items you must know to manage inventory well. This is the amount of time it takes from placing an order with your supplier to your product being available at Amazon. What is the worst case scenario in terms of days?

If you’re a private label seller importing from China, typically 90% of the time your stock arrives in 30 days, but 10% of the time it’s 45 days.

Typical problems that lead to a delay, like wire transfers, delays at customs or even a backlog at the port.

Using 30 days as your lead time, for 10% of the time you might have a 15 day stock out. I would rather take the 45 days as my lead time, or add in some days to account for delays.

Remember, when calculating lead time to account for the time to actually deliver to Amazon. This can add several days depending on how far inventory is traveling.

Never buy fewer days of inventory than your lead time. As an example, for that 45 day lead time, I would probably triple it to purchase 135 days of inventory.

Sales Velocity

This tells you how many units you sell per day. You can then calculate how many units 135 days (or whatever number you have) of inventory actually is.

Be careful calculating sales velocity if you’ve had a stock out during the month. Count only your days in stock. This is very important as it will throw everything else off.

Seller Central estimates are often inaccurate because it doesn’t include those days of stock being out.

Now:

Let’s look at a quick example to illustrate. Say you were out of stock for 10 days of the month and sold a total of 800 units.

Taking days out of stock into account, your sales velocity would erroneously be calculated as 27 units per day. (800 divided by 30).

Realistically, that calculation needs to be 800/20. (for the days you had stock) Which would give you a sales velocity of 40 units per day.

Now consider that you may be ordering 135 days of stock at a time. The first calculation would tell you to order 3645 units. Whereas the second one, accounting for the days out of stock tells you to order 5400 units – a significant difference!

Safety Stock

This is extra stock that you keep on hand as “insurance”, when you experience a swing in sales velocity.

There isn’t really a hard and fast rule about how much safety stock to keep.

But, if i’m calculating it manually I typically want enough safety stock to cover half of the lead time.

Inbound Inventory

This is simply any inventory that you already have inbound, on its way to Amazon. Always add this number to your current inventory so you don’t over-order.

Reorder point

This is the number of units left in stock at which point it is time to place a reorder. This number is based on the metrics of sales velocity and lead time.

The Excel tool I designed will automatically calculate this if you input correct numbers in the other columns.

Here’s the deal:

What about Q4?

We often get asked about making inventory calculations for the fourth quarter.

honestly, without historical data there’s no easy way to do so, especially if it’s your first Q4.

Come up with your best estimate — for example, you might expect selling three times more than usual.

One suggestion is to look at Google keyword search volumes and use that as a proxy. For example, perhaps you find that there are twice the usual number of searches for your particular keywords in December.

Ordering New Products

Another common question is how to calculate what your unit number should be on an order for new products. A key mistake here is that sellers can become over-cautious.

It’s one thing to test the validity of your product.

But don’t buy so little that you set yourself up for failure. Don’t do that especially if you have longer lead times.

For those wanting to make a calculation for themselves, I created another free Excel-based tool which you can download here.

There are a couple of things you should consider:

- Are you going to have a certain number of promotional units? If so, include these in your order but exclude them from any calculation of sales velocity later on.

- Look at the top 10 or so sellers and how many products they likely sell per day. This is one way of estimating sales velocity for an initial order.

- Air vs. Sea freight. People tend to look solely at profit and loss, then often forgetting the lead time. The longer your lead time, the more likely you are to encounter a stock out. While sea freight is cheaper on the surface, look seriously at air as an option too. It’s faster, you can make smaller orders more frequently and you can keep up with varying demand.

Sellers take cheaper sea freight and choose to have a period of stock out with the longer lead times. All things considered they would have made more money by using air freight despite the higher freight costs.

Bottom line – don’t ignore air freight just because it’s more expensive.

Wrapping This Up…

Managing your inventory well can prove to be one of the best investments you can make in your business. Marketing and optimization efforts won’t matter if you run out of stock!

For anyone who would like some free templates to get started: download the inventory forecast and initial order calculation templates here.

If you’d like a solution which automates forecasting and Amazon inventory management for you, then that is exactly why I built Forecastly. It came from my own frustration with having stockouts and losing valuable profit. So it is built to include a range of advanced features you may need.

Special Offer…

Managing inventory and scaling your Amazon business is covered in our completely updated and brand new Amazon business course that teaches first time entrepreneurs how to launch their very own physical product Amazon business. If you want to check that out and see if it’s right for you click here…